Lowrider

In Short:

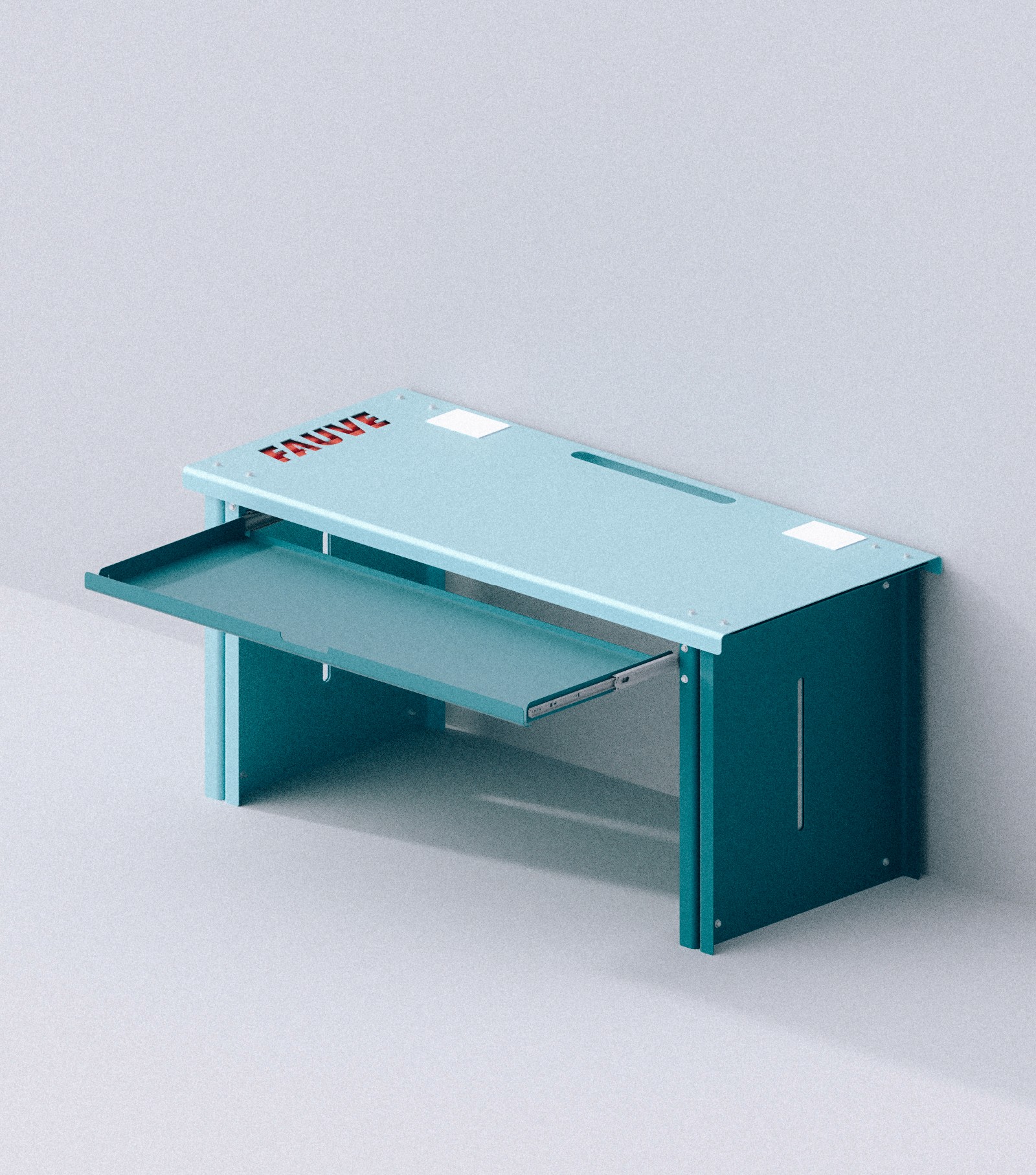

FAUVE Creative Space, a new collaborative workspace in Portsmouth, Ohio, needed a signature work desk that embodied their bold, material-forward aesthetic while solving practical workspace challenges. The brief called for mobility, integrated cable management, and a sculptural presence, all within a tight budget.

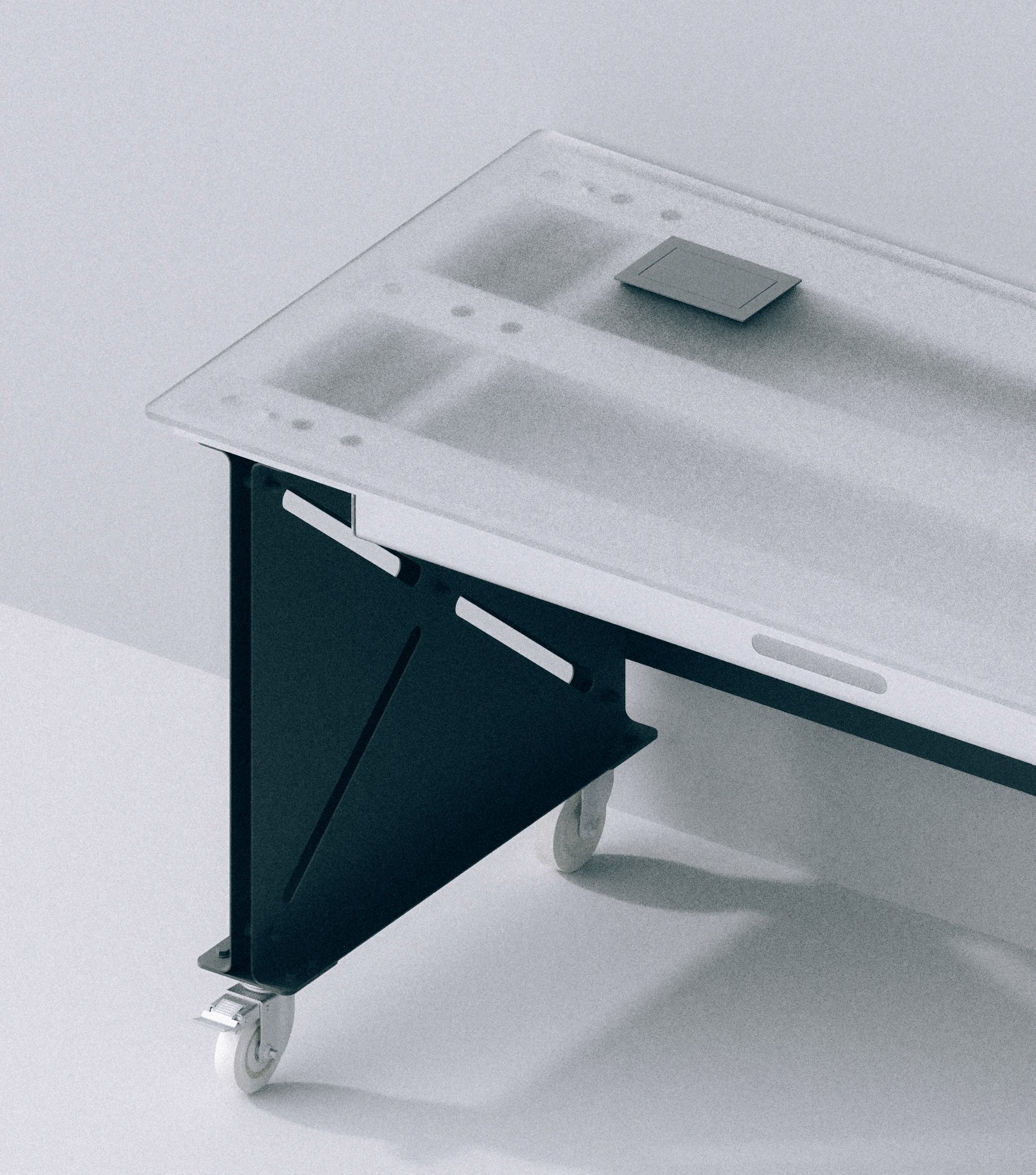

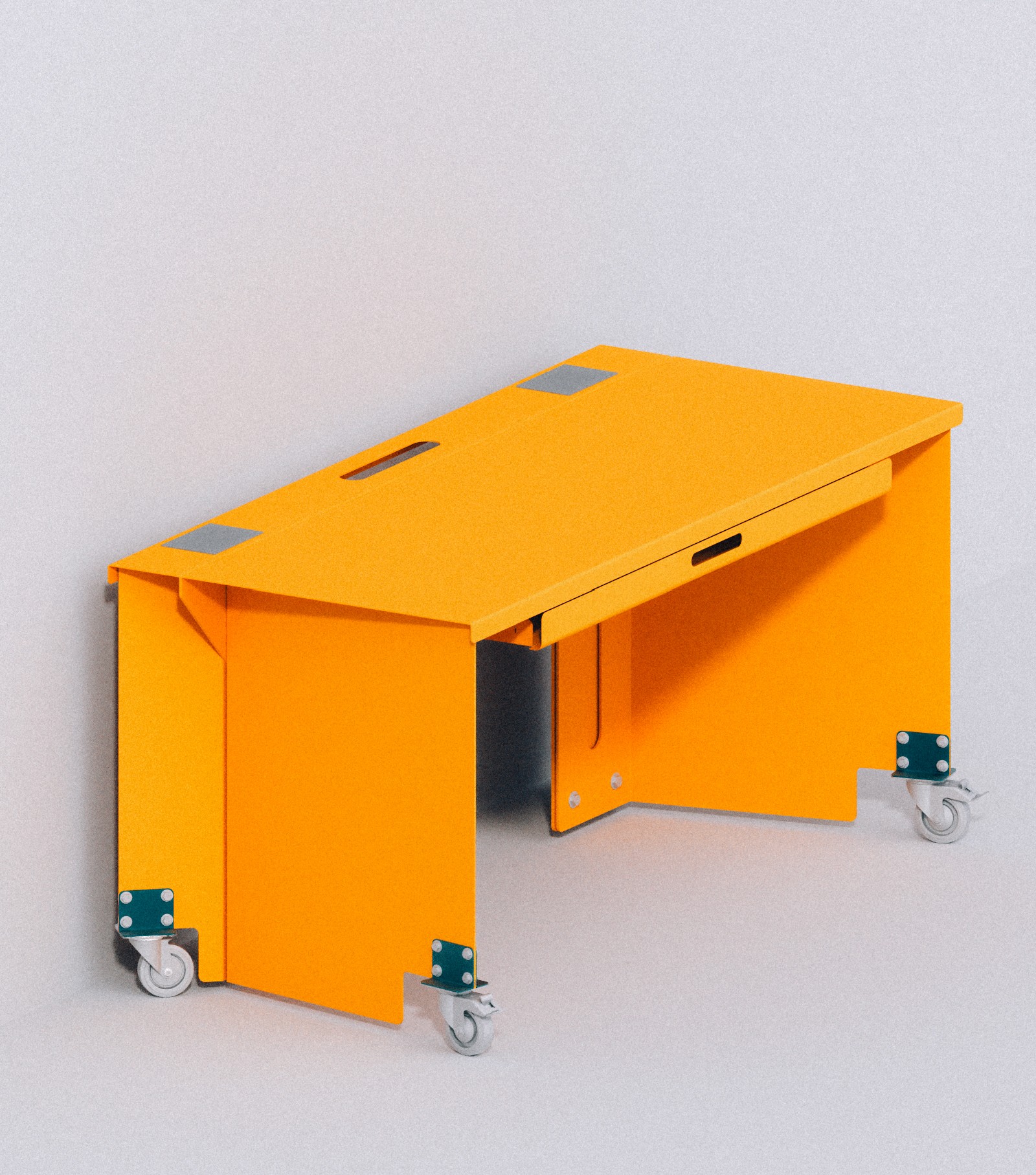

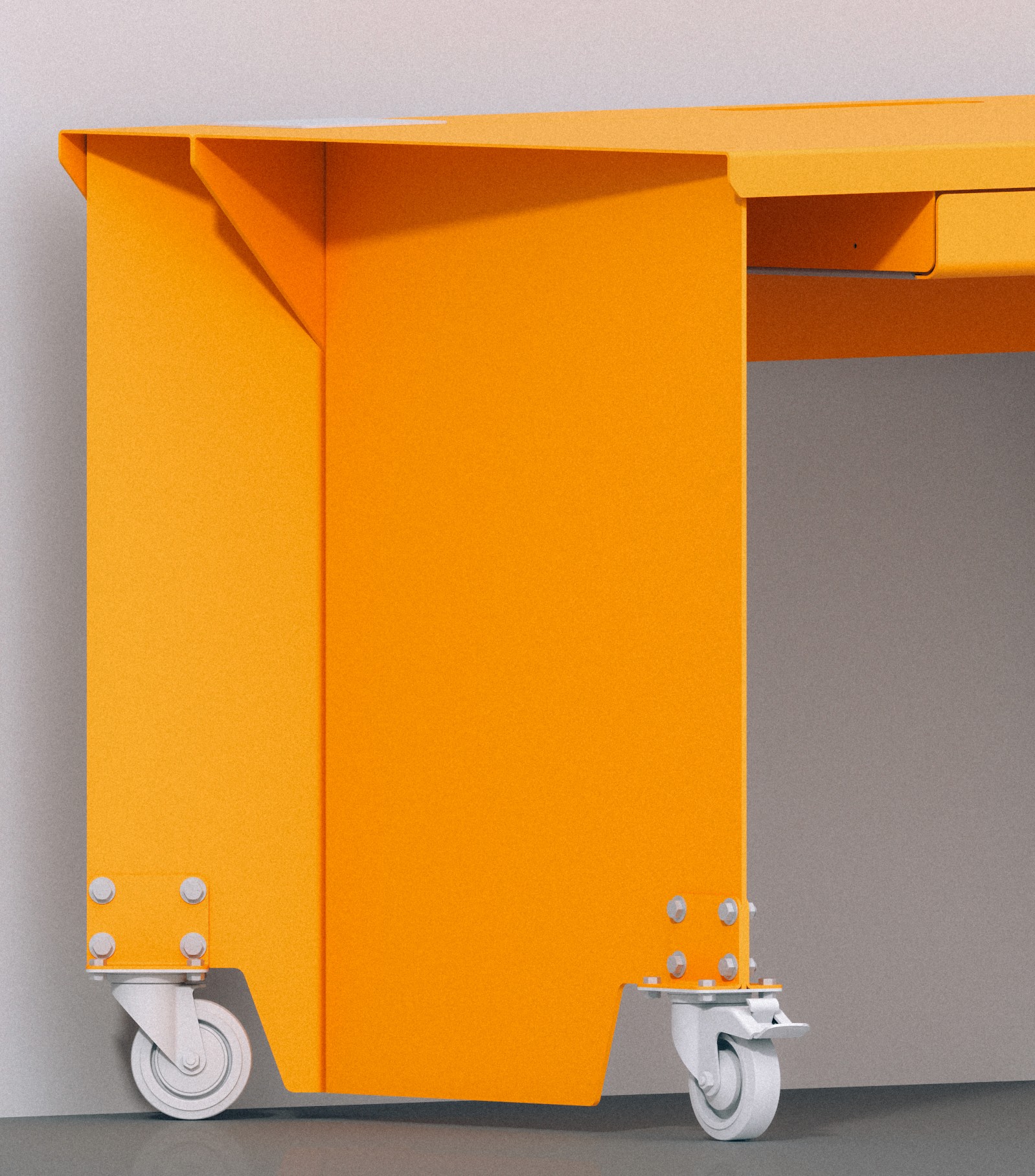

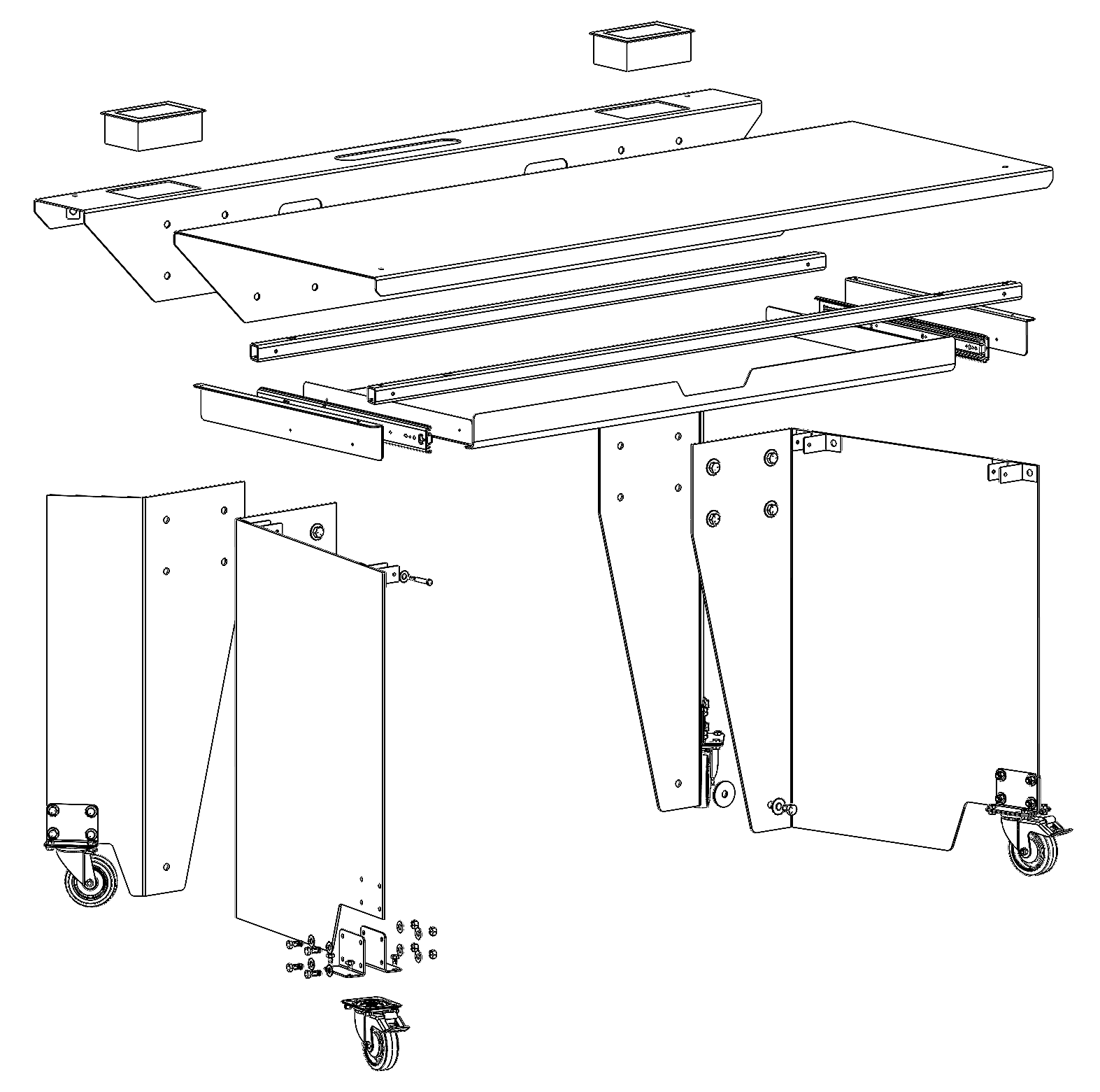

I developed multiple concept options exploring different structural approaches and material expressions, ultimately landing on the "Lowrider". A mobile work desk with powder-coated steel construction, integrated drawer with cable management, and locking casters for workspace reconfiguration. The angled leg geometry creates visual dynamism while maintaining structural stability, and the vibrant tangerine orange finish reinforces FAUVE's playful, bold design language.

Through value engineering and careful material selection, I delivered a design that meets budget parameters without compromising quality. I've coordinated with fabricators and developed complete manufacturing documentation—the desk is ready for production once FAUVE finalizes their location. The project demonstrates end-to-end design development from concept through fabrication-ready deliverables.

Client

FAUVE

Category

Custom Furniture

Location

Chicago, Illinois

Year

2025/2026

Skills Used

SolidWorks

Keyshot

Adobe Suite

Fabrication Drawings

Physical Prototyping

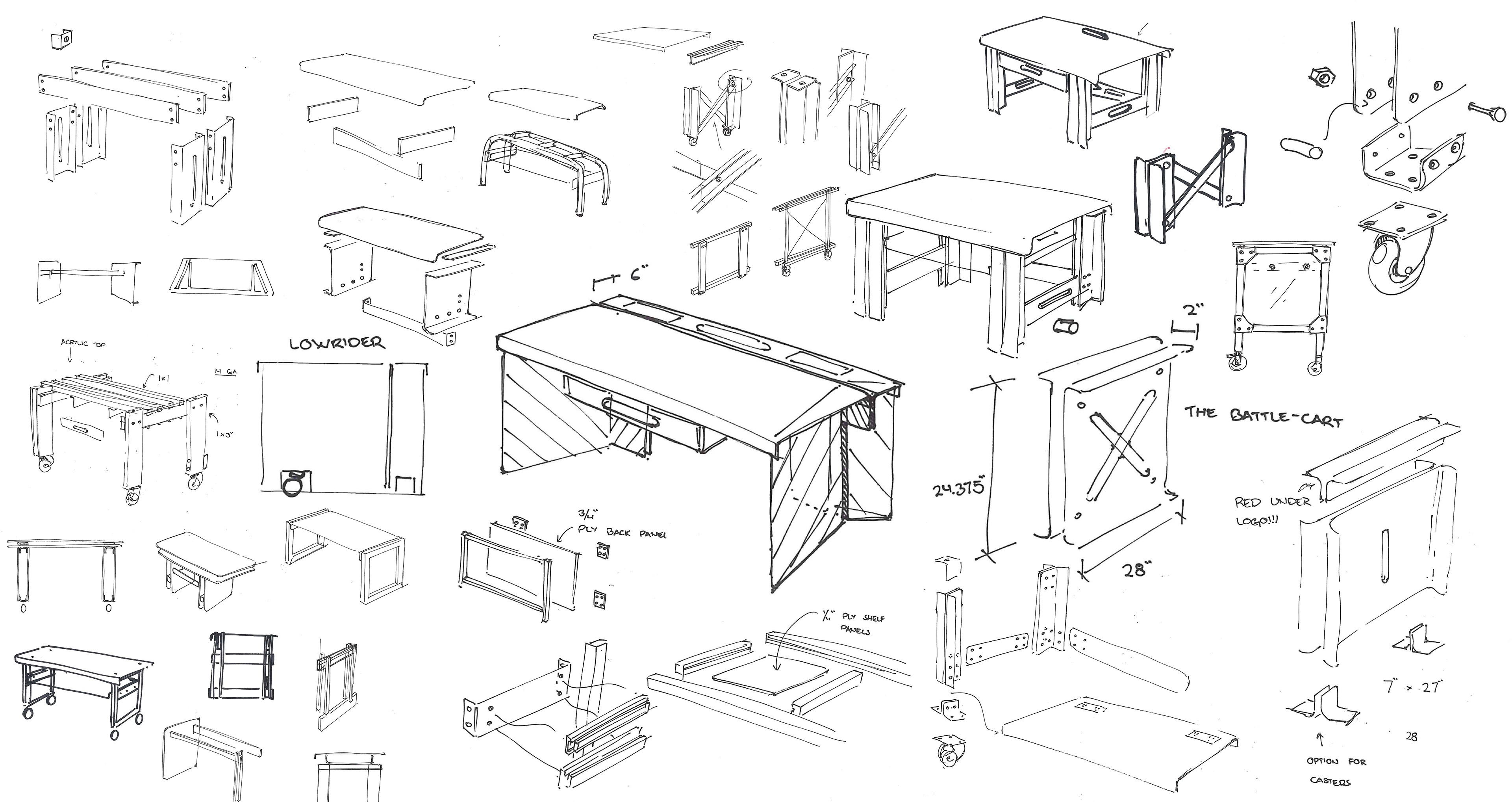

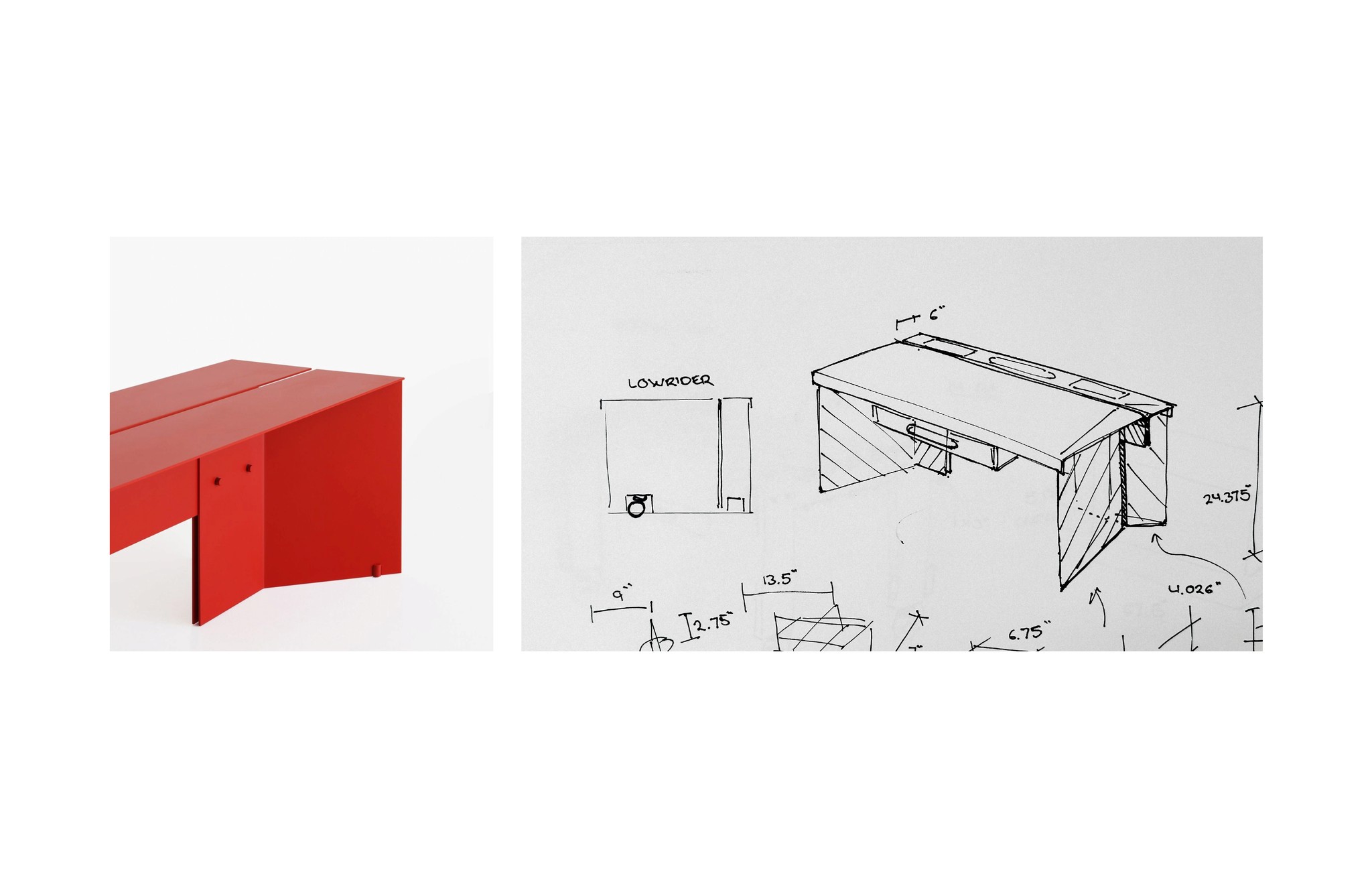

Hand Sketching

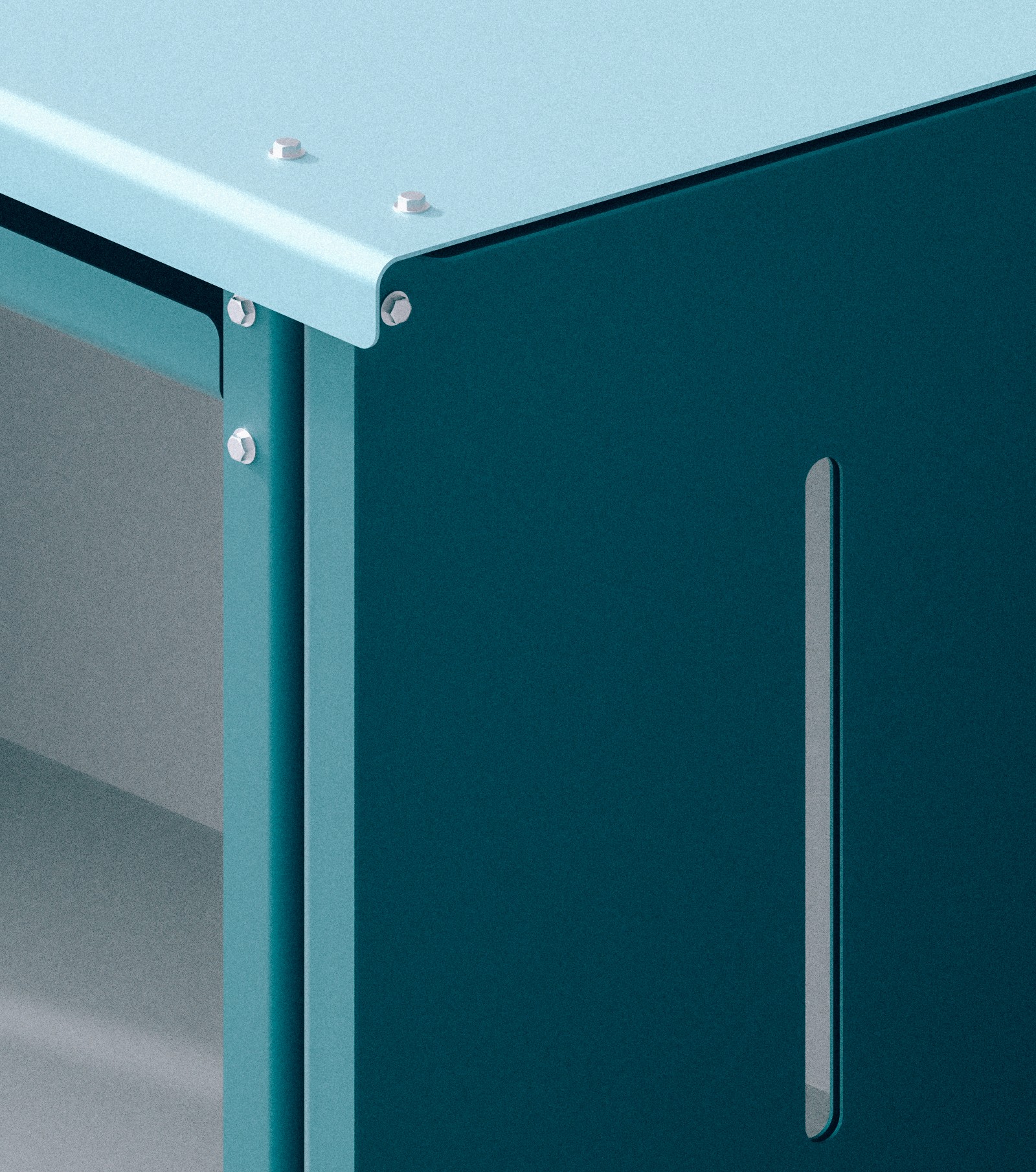

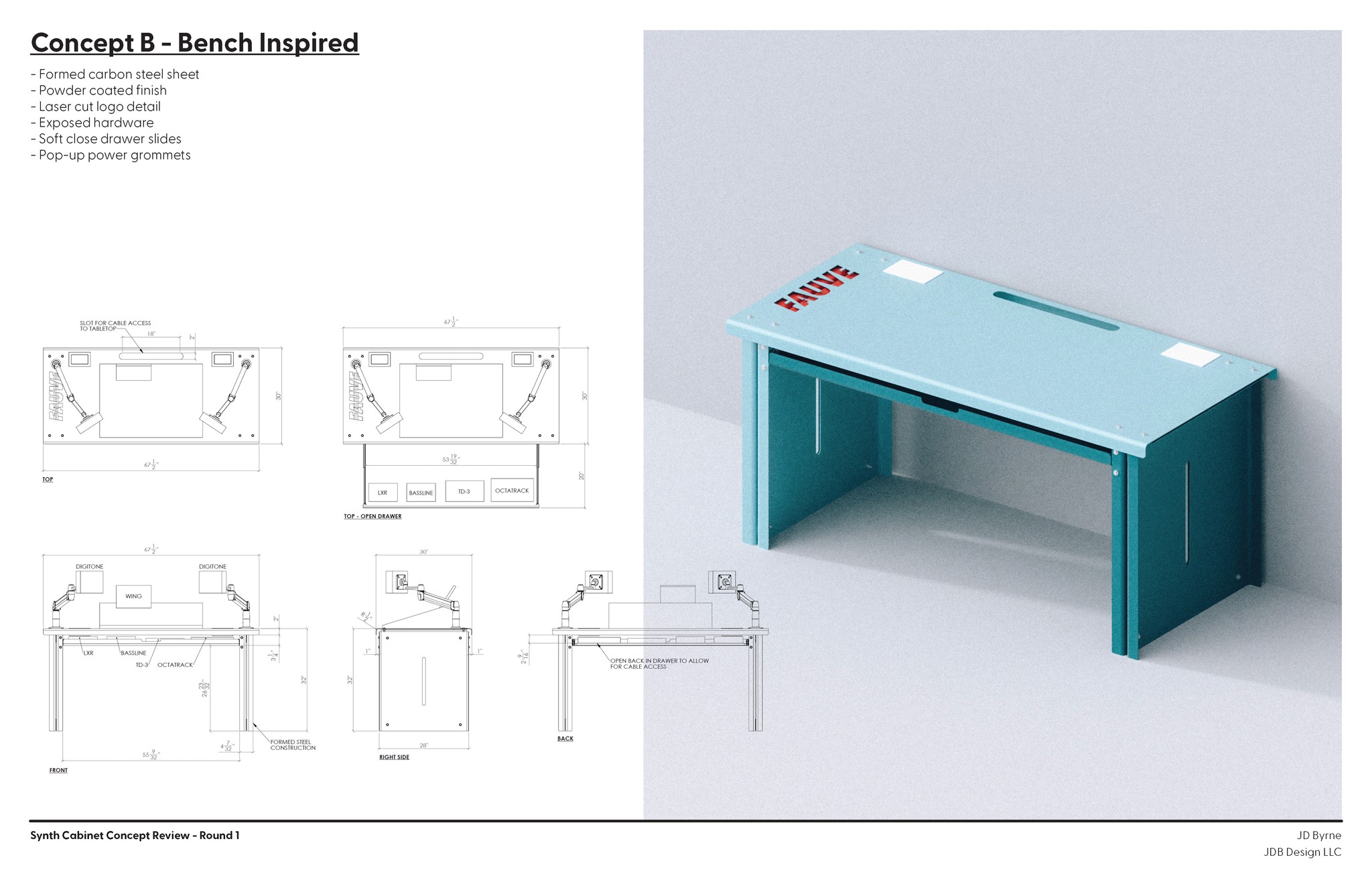

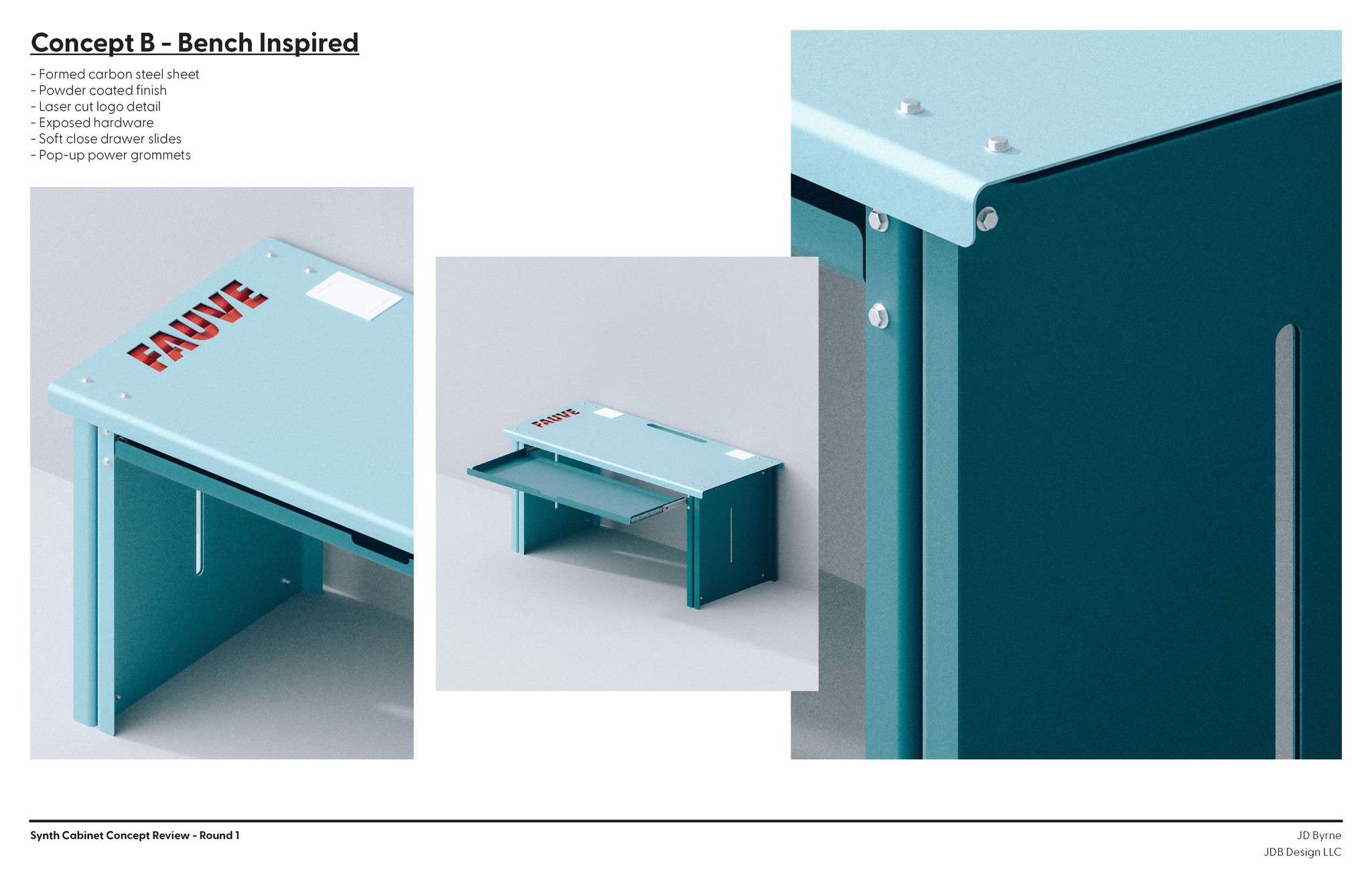

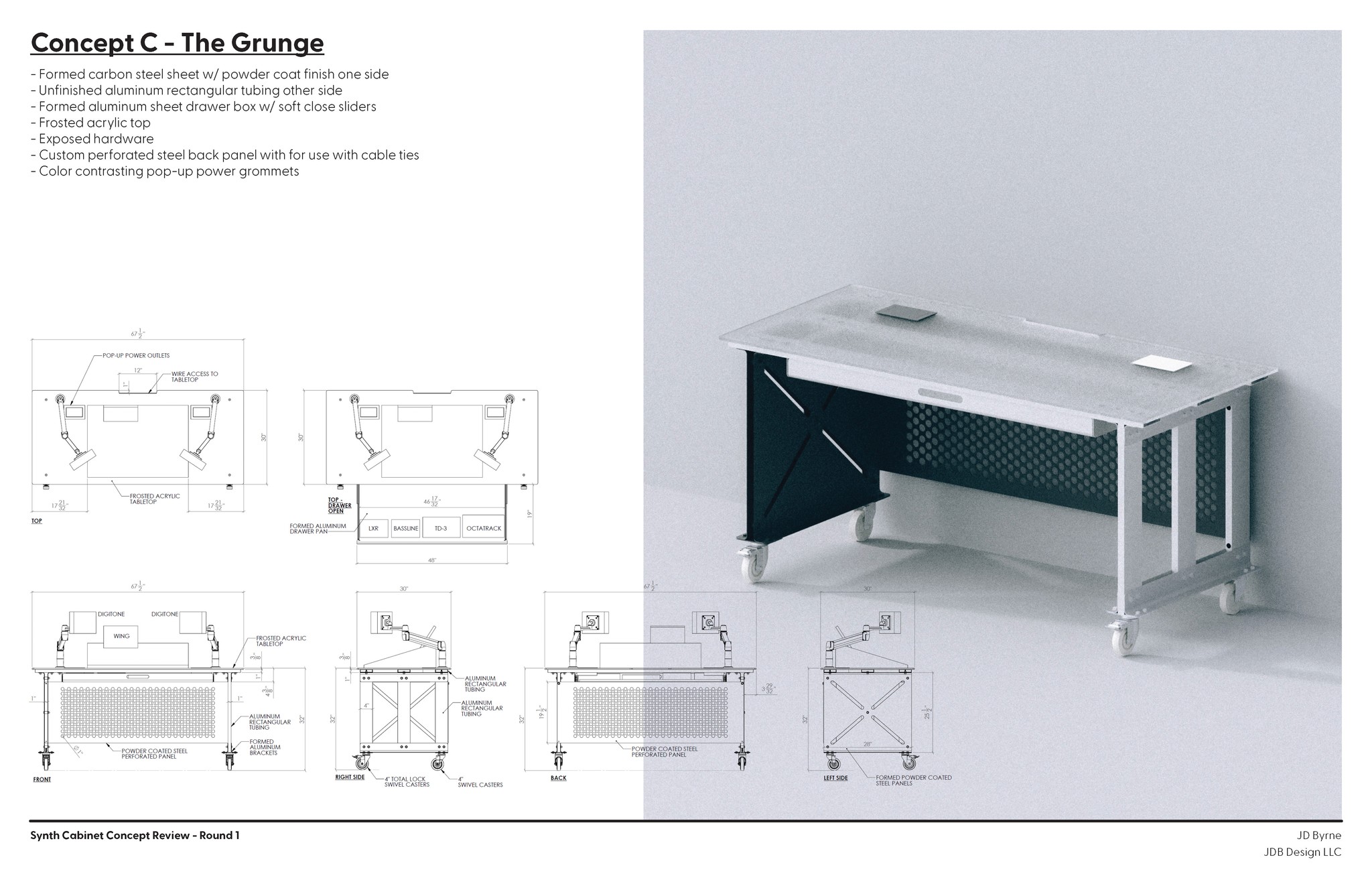

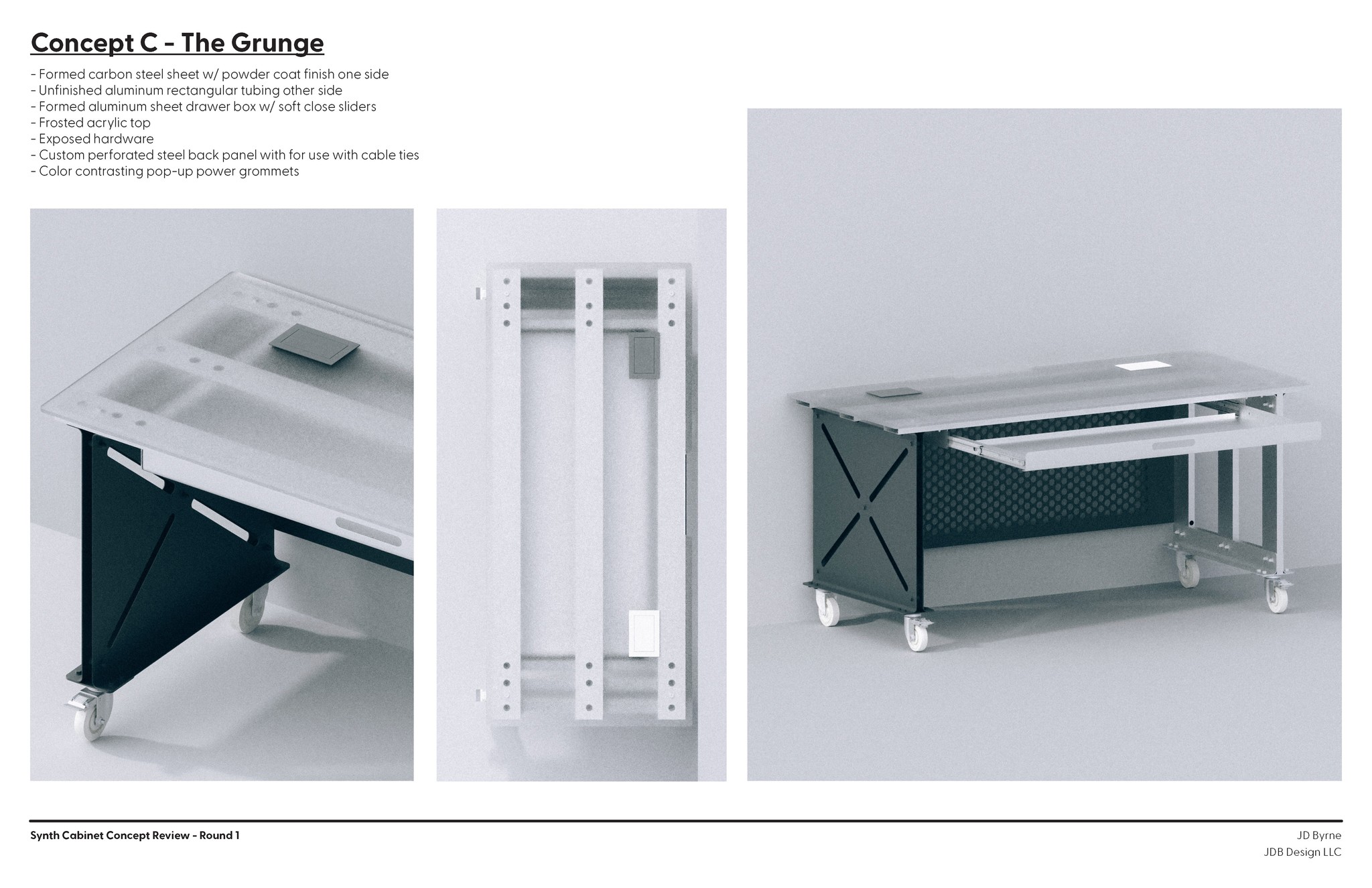

FAUVE's Supplied Inspiration

FAUVE's desired aesthetic was centered on bold industrial materiality with a playful twist ~ vibrant powder-coated metals, exposed fasteners as design details, and sculptural formed sheet metal. The direction was clear: unapologetically colorful, structural, and modern.

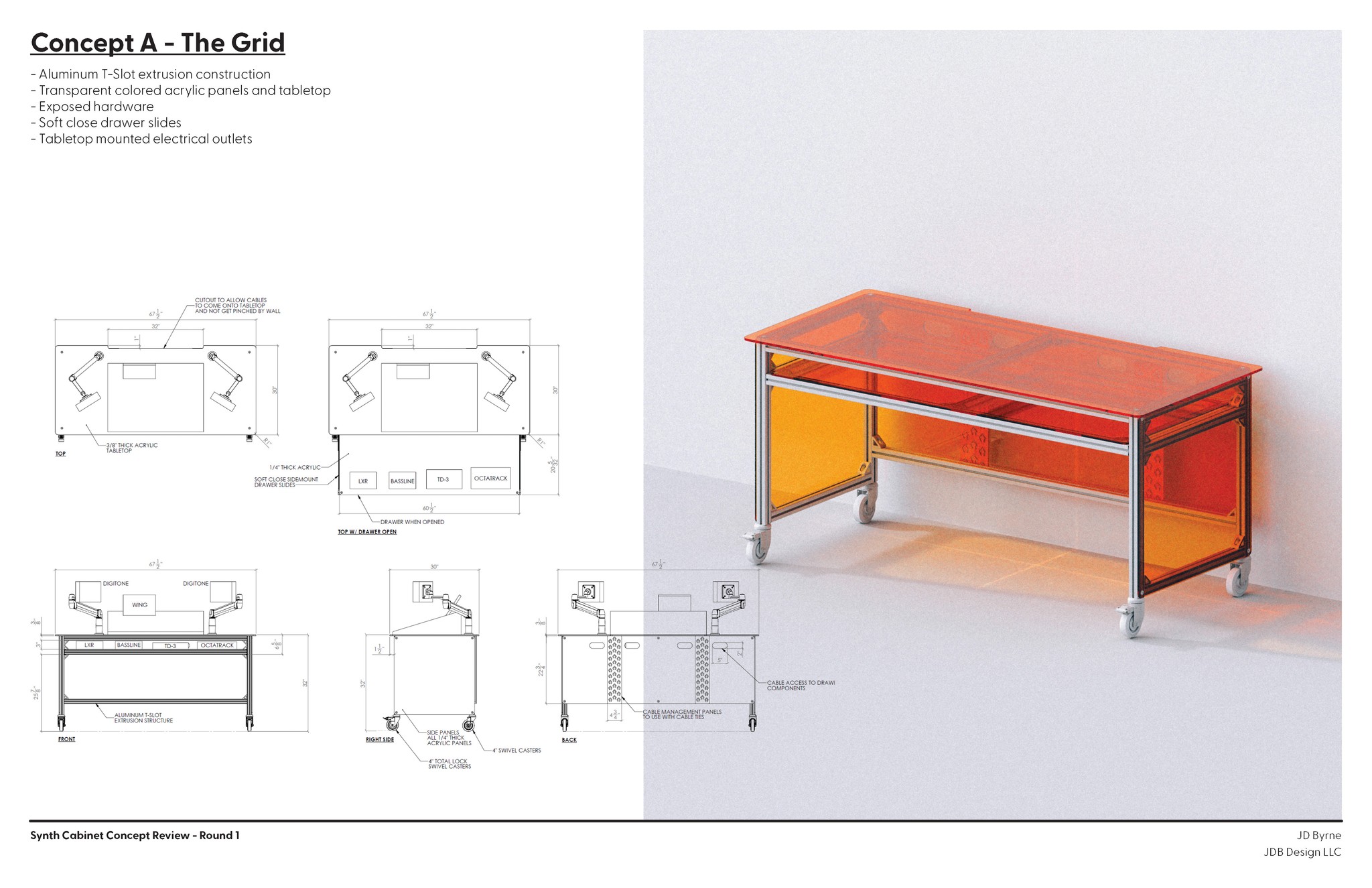

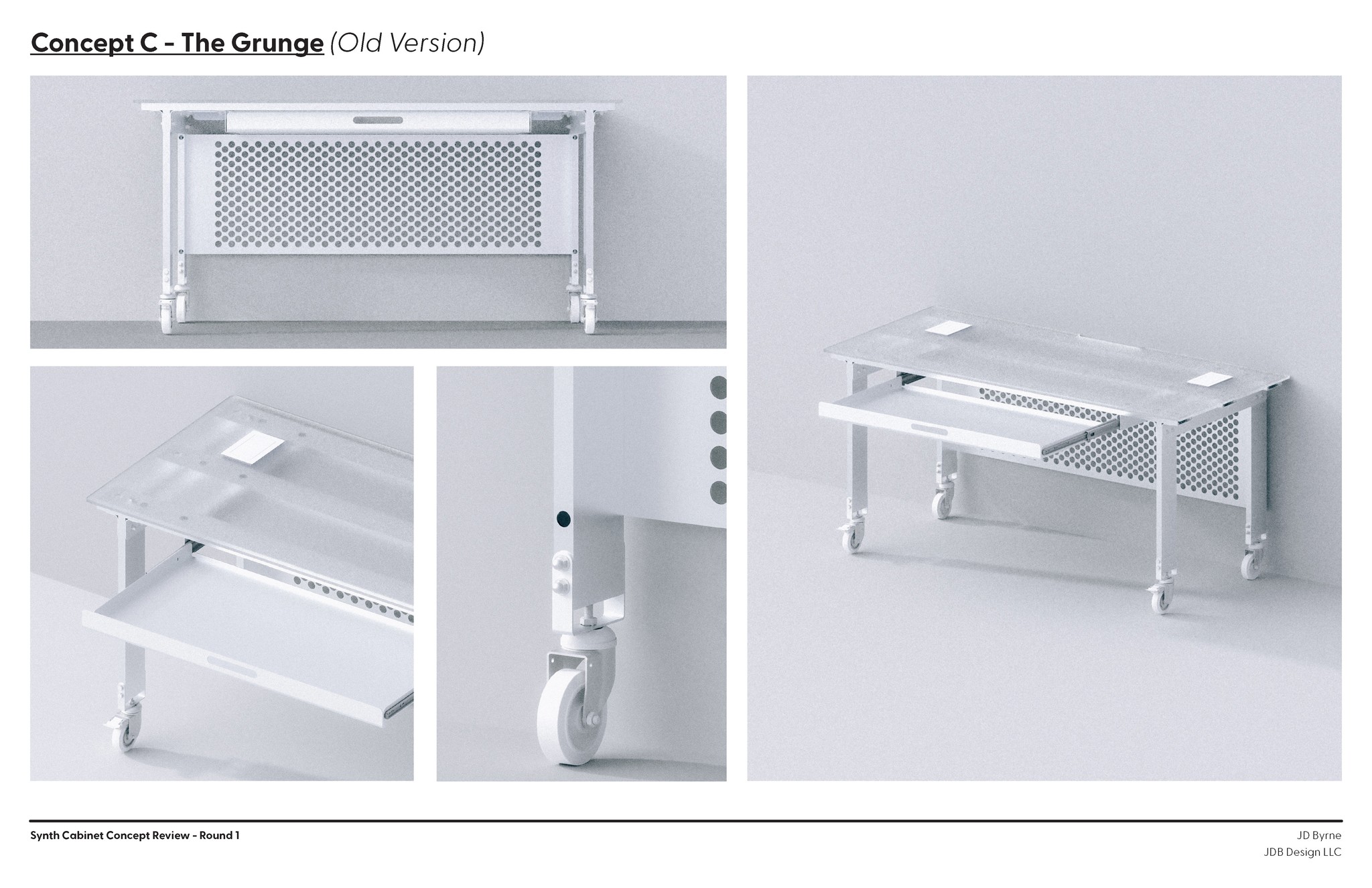

Initial Concept Creation

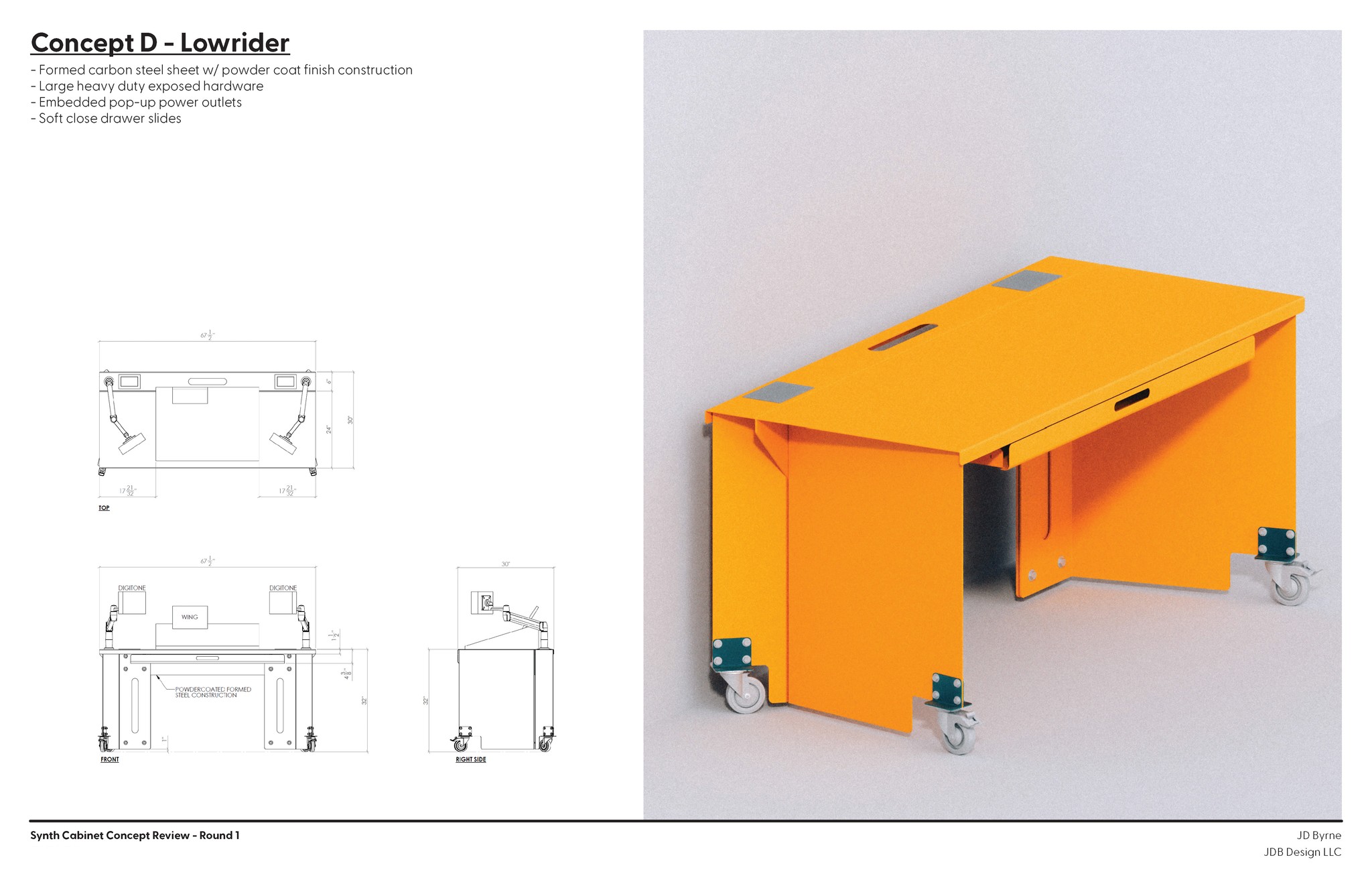

The FAUVE team chose Concept D: The Lowrider to proceed with.

Concept Refinement

FAUVE:

"We love this concept, and wanted to see if you could add some additional angular details?"

To add more angularity, and not deviate too far from the already successful concept, I decided to notch corners that I felt could be omitted.

Final, Approved Concept

Engineering, BOM Creation, Material Sourcing, Manufacturing Prep

Once concept was approved, the following was taken care of:

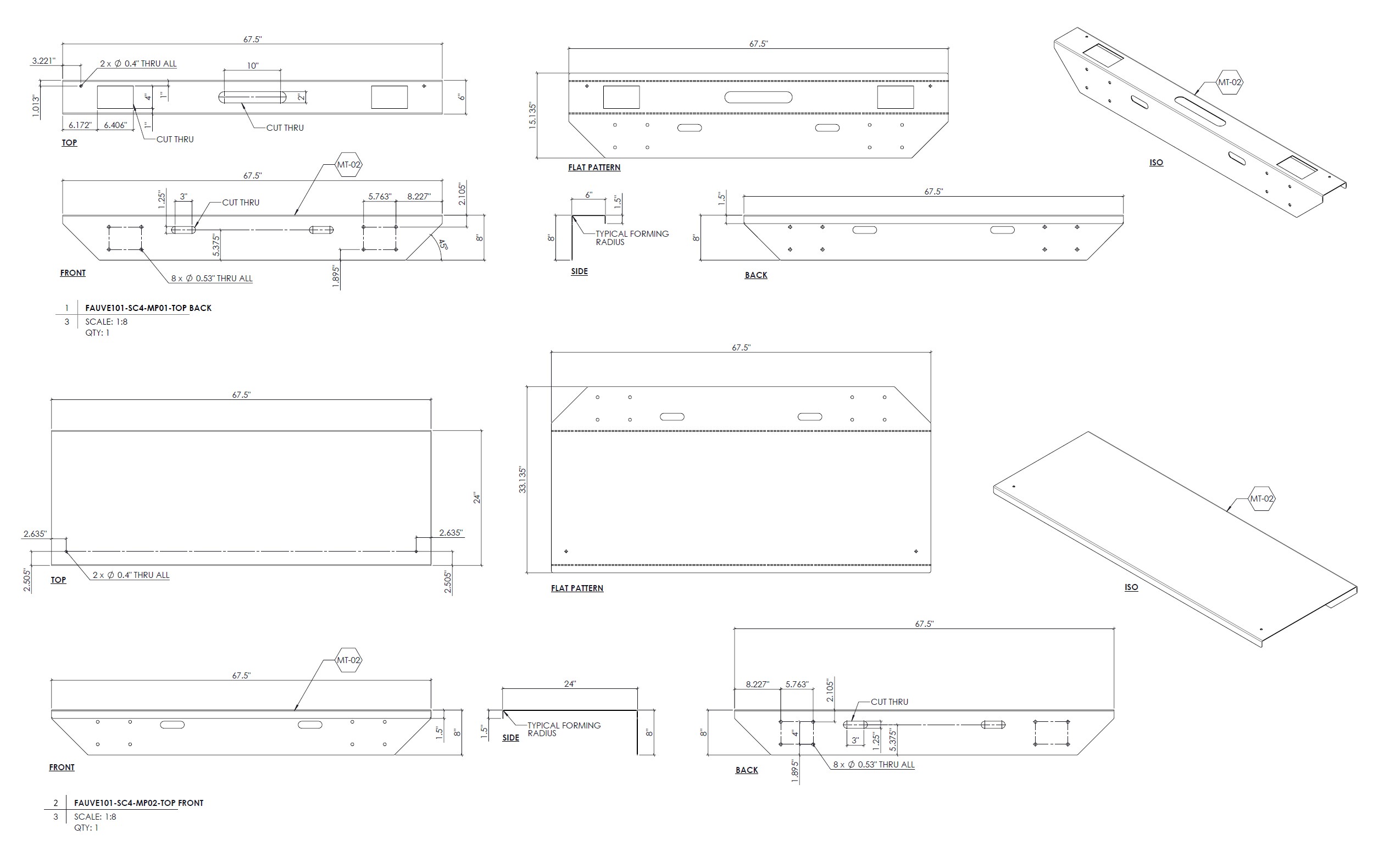

Creating all technical documentation of needed part fabrication, including technical drafting's, material specs, finish specs, and flat patterns for laser cutting.

Organizing manufacturing with a local Chicago metal shop.

Sourcing all needed hardware and misc components