Lemonaide Cane - Handle and Foot Design

In Short:

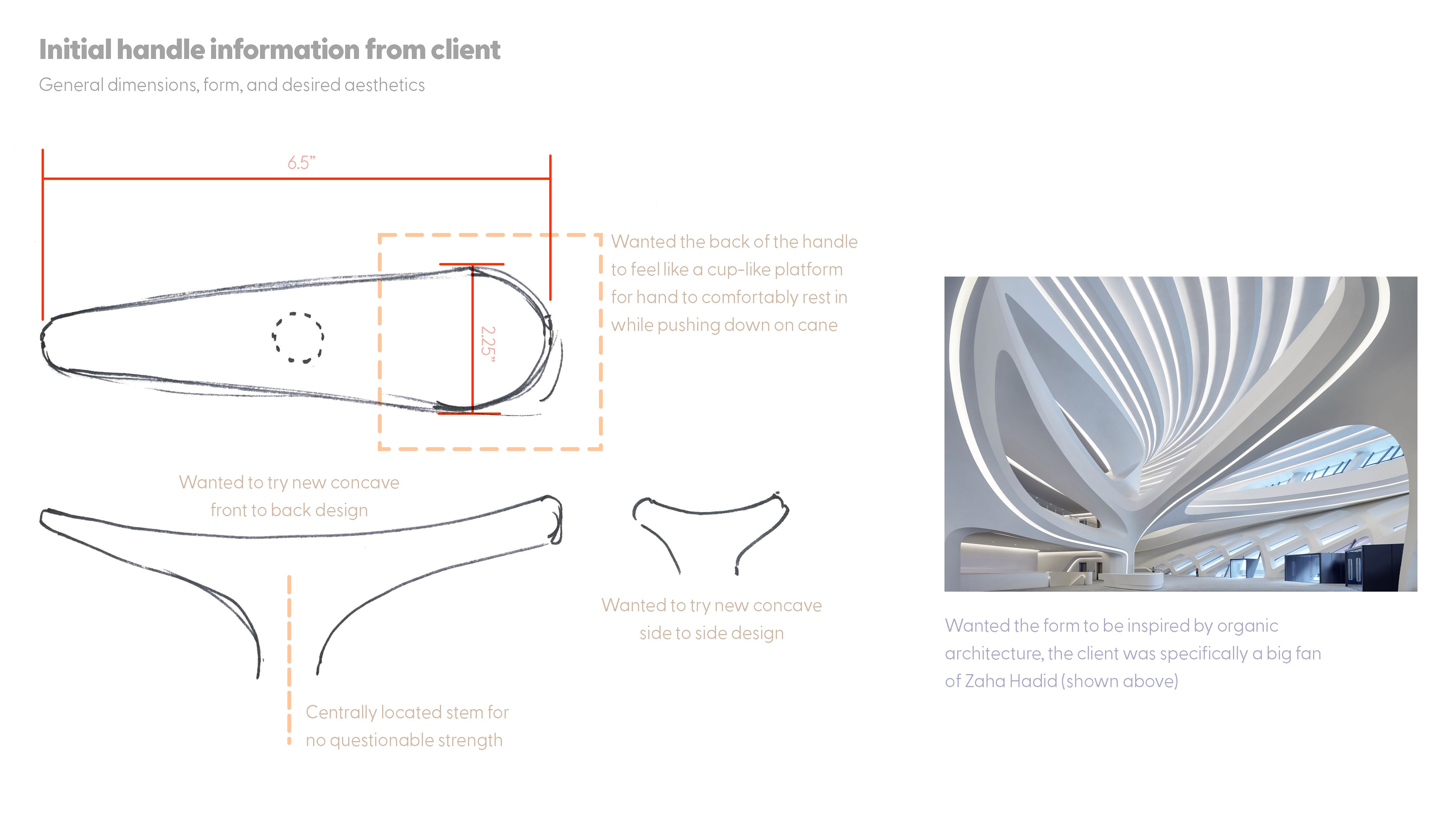

For an innovative startup redefining the traditional walking cane, I was brought on to develop the ergonomic handle and stylistically aligned foot component while the stem (containing an internal extension/retraction mechanism) was engineered by a mechanical specialist.

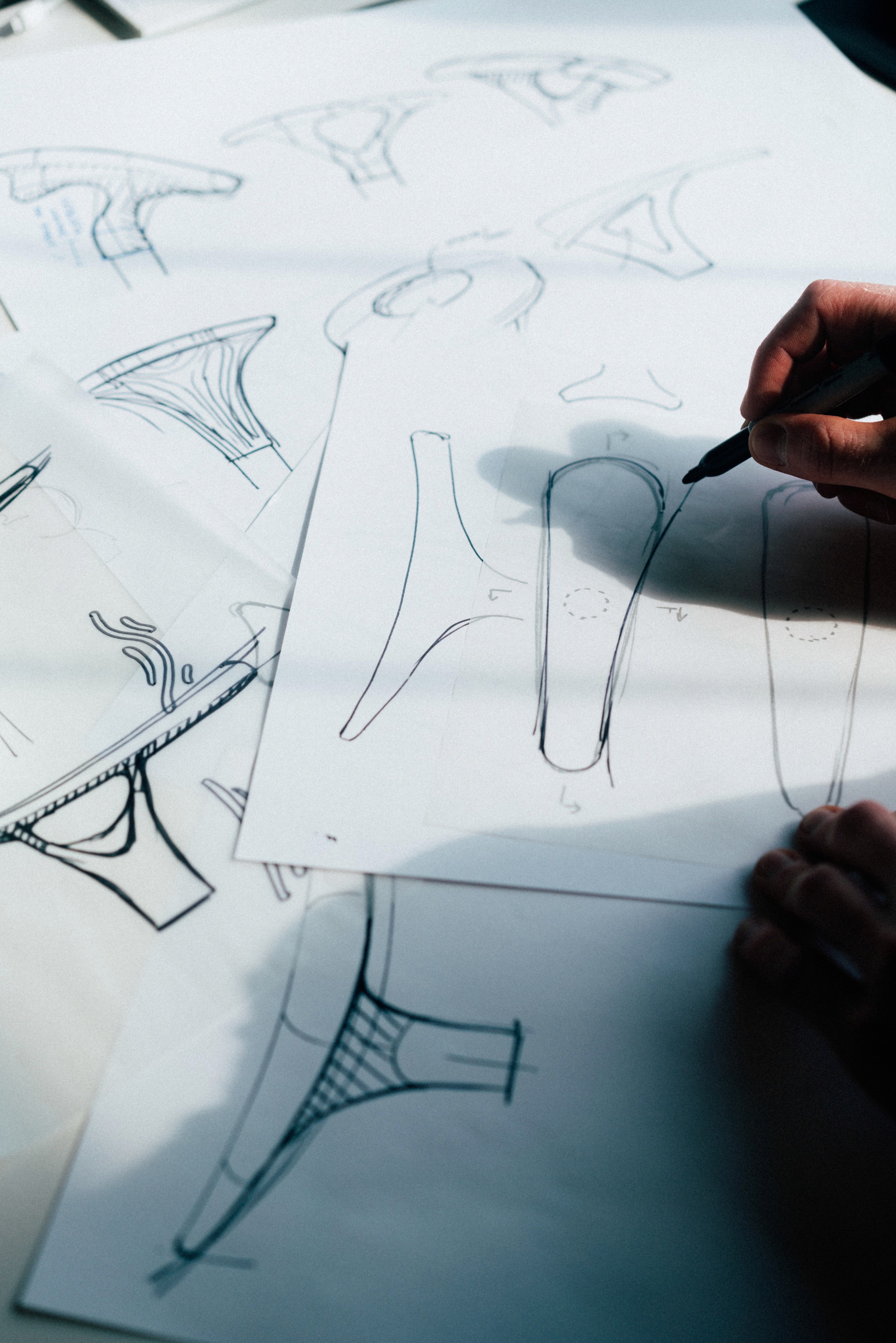

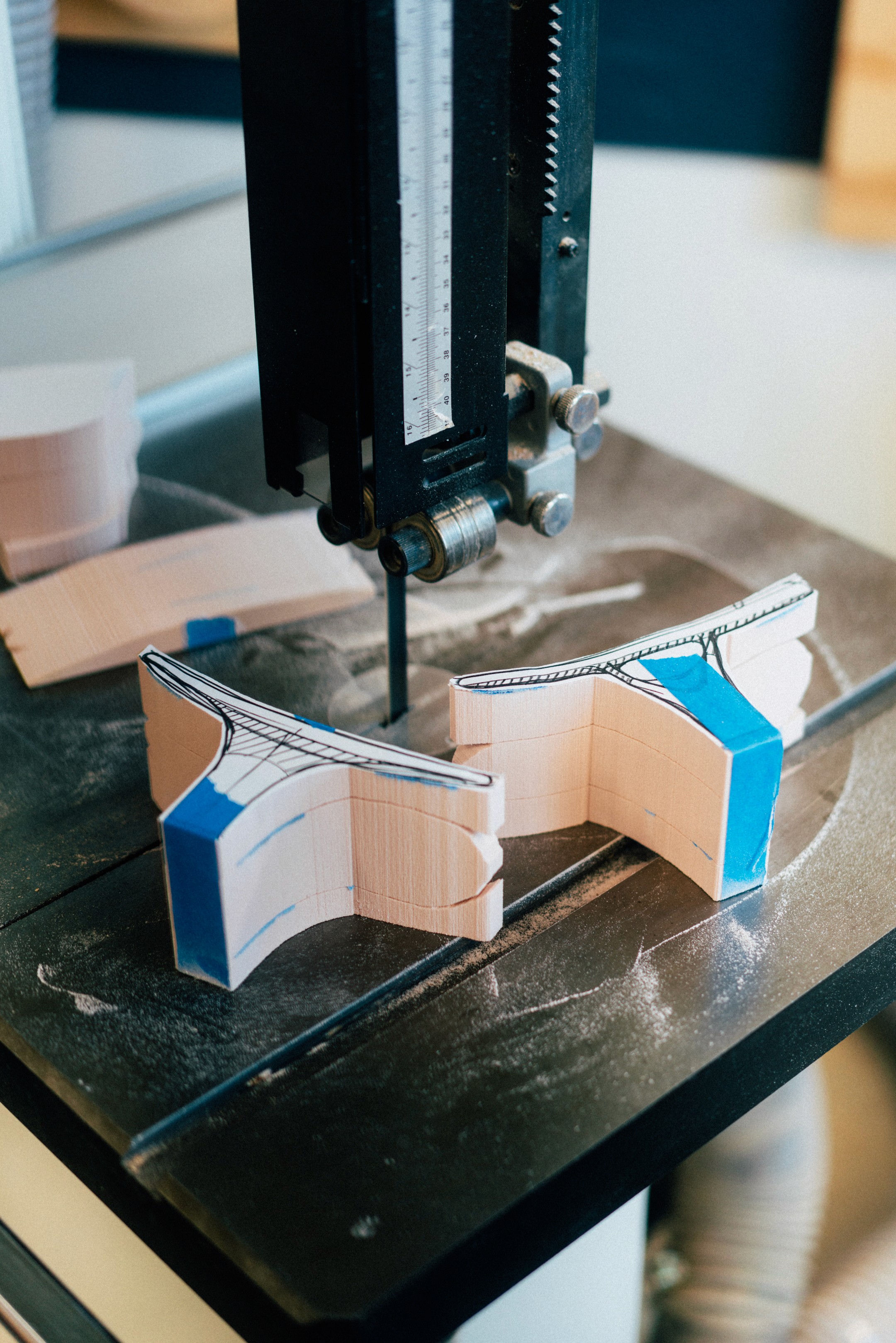

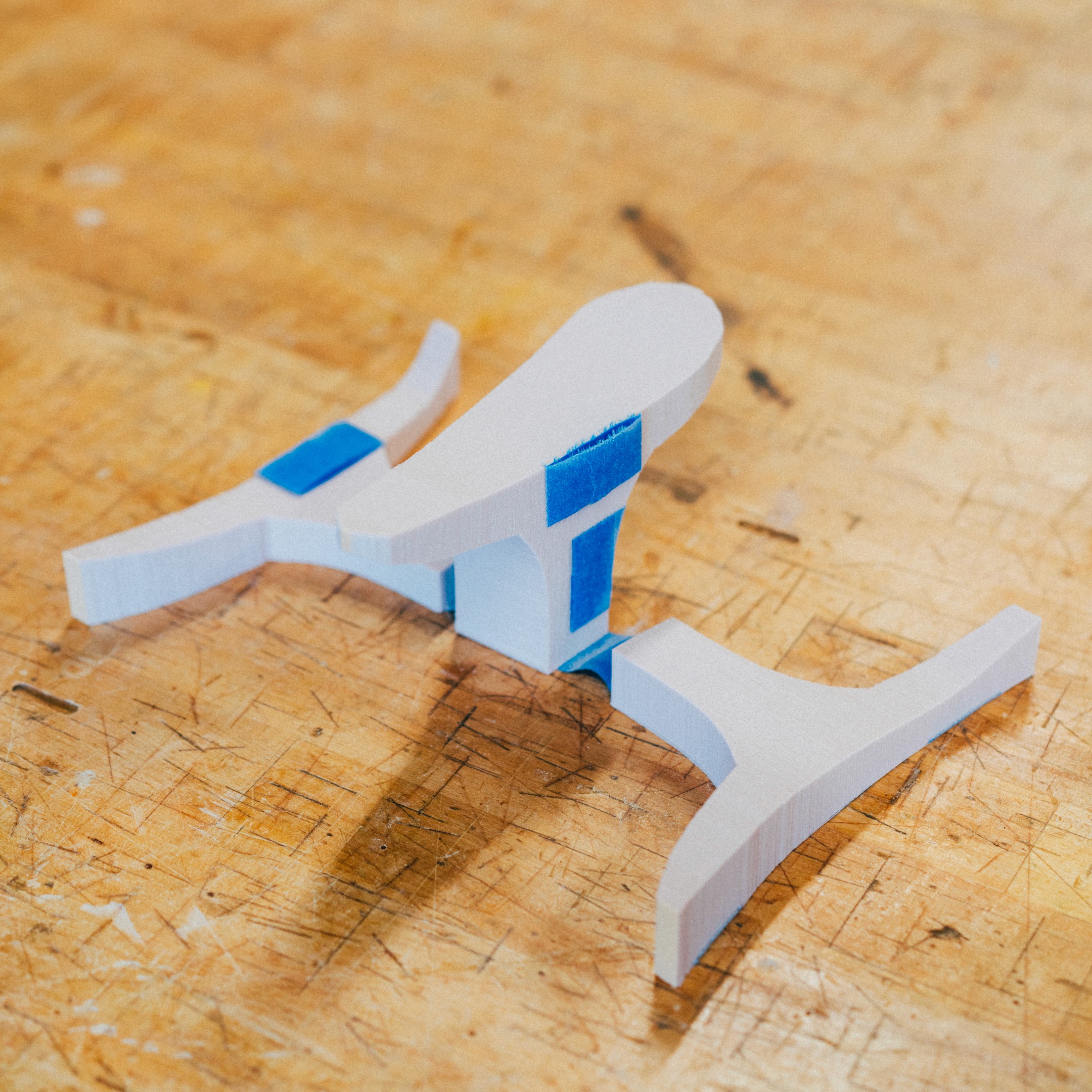

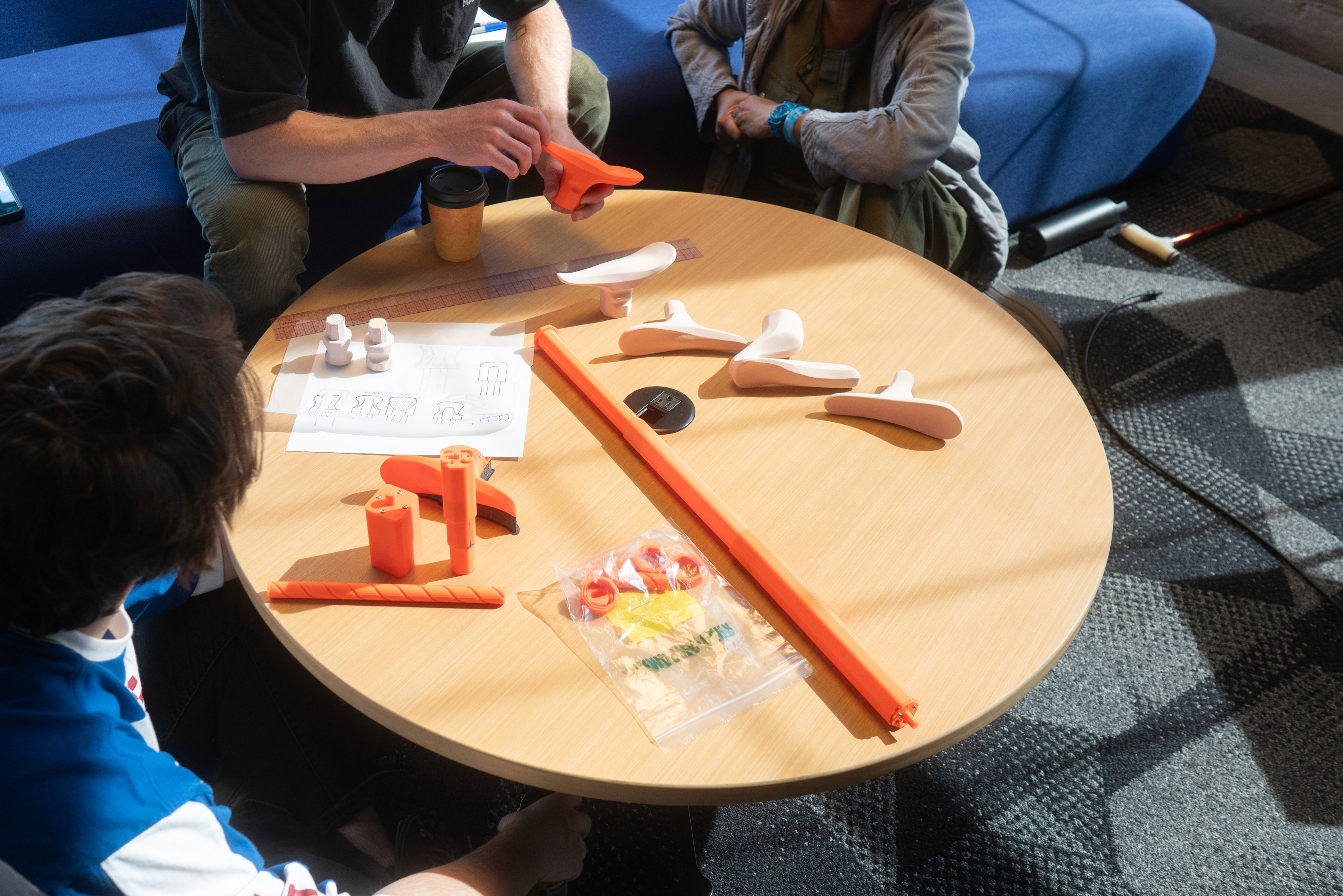

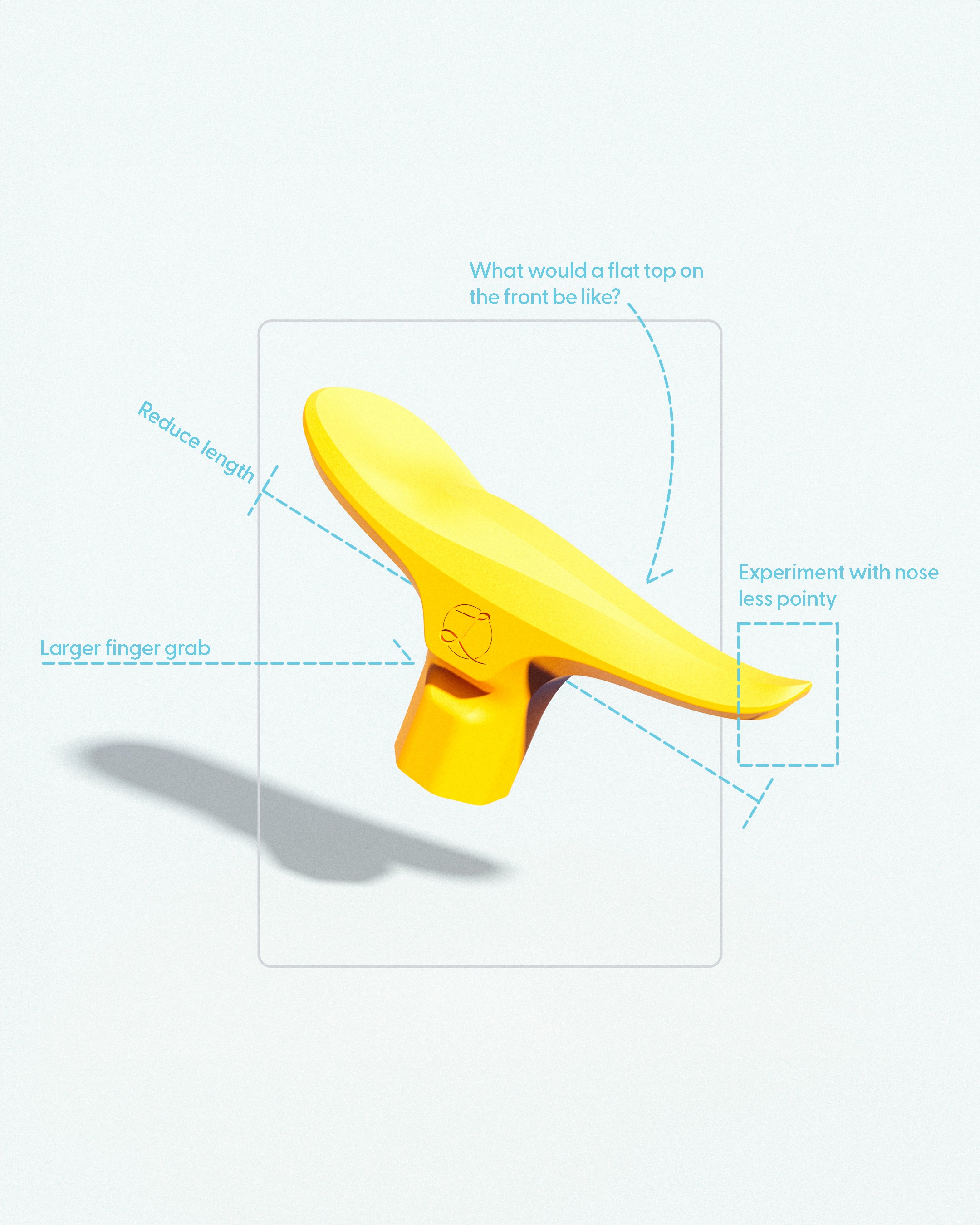

Inspired by elegant, organic architectural forms, the design direction prioritized both aesthetic expression and human-centered comfort. I began by hand-carving foam studies to explore and validate ergonomic form in real time, allowing immediate tactile feedback and rapid iteration.

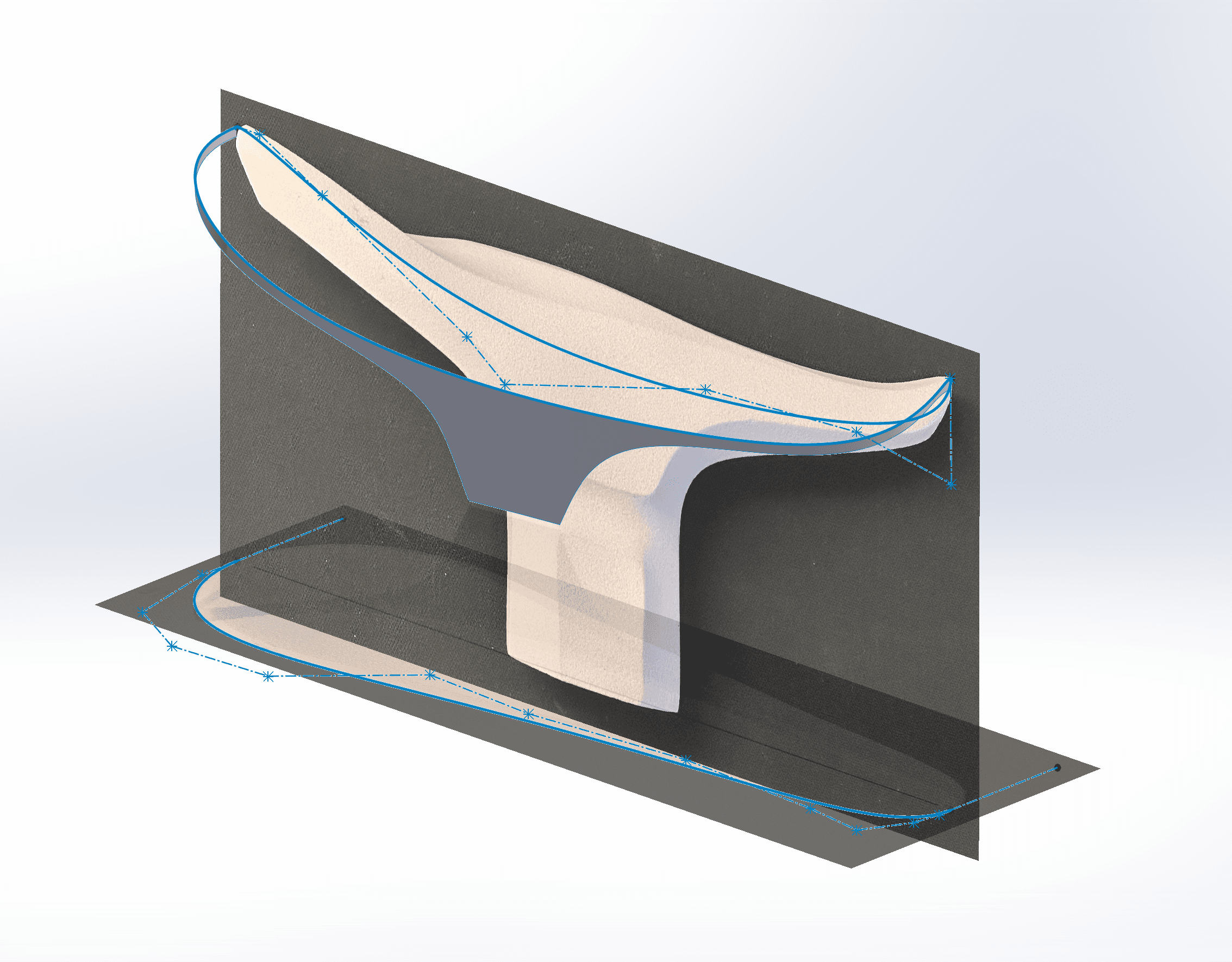

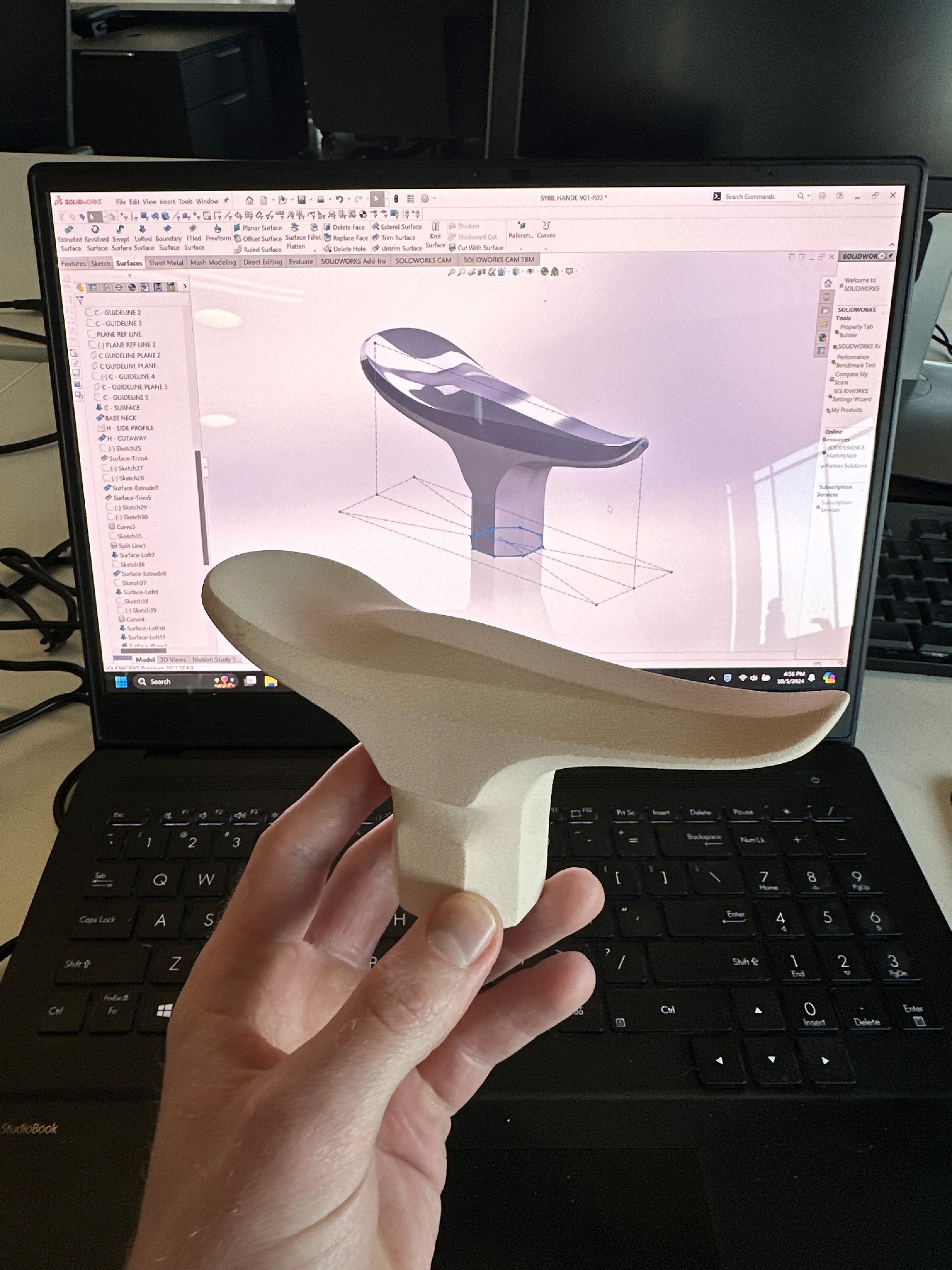

Upon concept approval, I translated the foam study into advanced SolidWorks surfaces and produced 3D-printed prototypes for additional user evaluation. Final refinements in CAD resulted in a fully approved, production-ready handle. A complementary foot design, sharing the same design language, was also developed and validated.

After prototype approval, I delivered all CAD and documentation to the engineering team to support further mechanism integration and fundraising efforts.

Client

Category

Consumer Product

Location

Chicago, Illinois

Year

2024-2025

Skills Used

Hand sketching

Foam model making

User interviews

Solidworks

Keyshot